Service Hotline

+86 13711845437

Manager Zhang

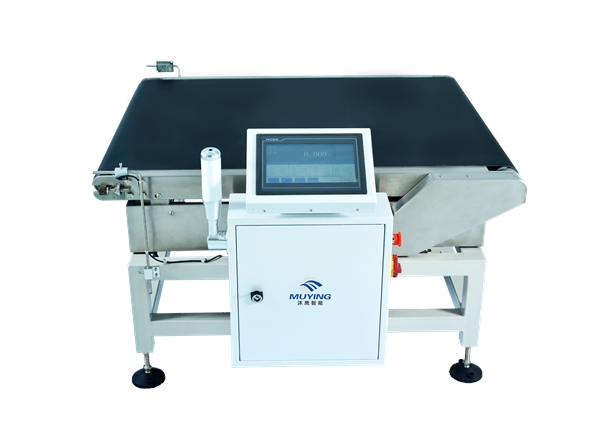

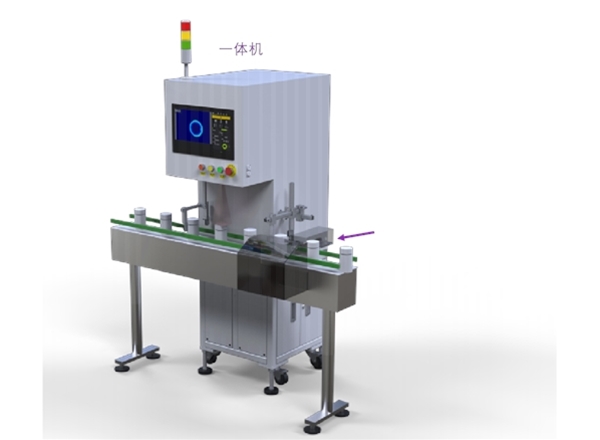

Product Details

Details

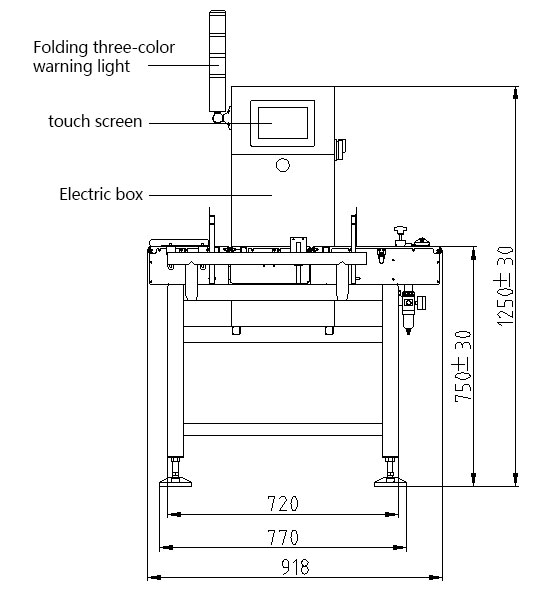

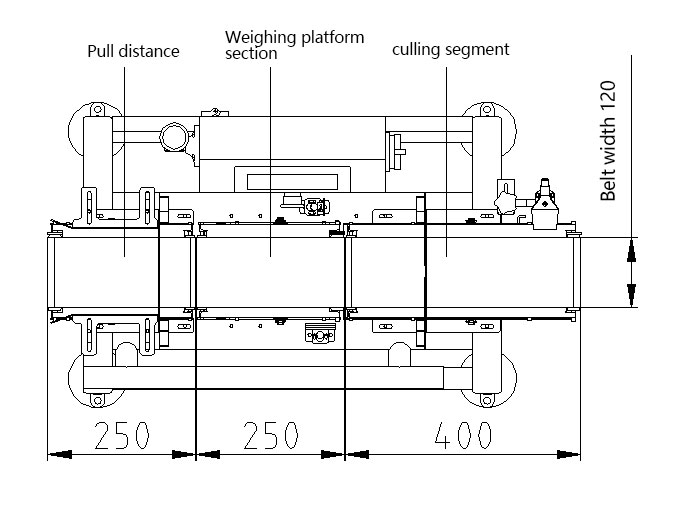

Dimensions

Scope of application

· This product is suitable for online automatic weighing detection, underweight detection, missing packaging detection, attachment missing detection, etc. of small packaging boxes, small bags, extremely small items, etc.; it is widely used in electronics, pharmaceuticals, food, beverages, health products, Daily chemical, light industry, agricultural and sideline products and other industries.

Product Features

l Strong versatility: the standardized structure of the whole machine and the standardized man-machine interface can complete the weighing of various materials;

l Simple operation: using the Welun color human-machine interface, fully intelligent and user-friendly design; the conveyor belt is easy to disassemble, easy to install and maintain, and easy to clean;

l Adjustable speed: the frequency conversion control motor is adopted, and the speed can be adjusted according to the needs;

l High-speed and high-precision: high-precision digital sensors are used, with fast sampling speed and high precision;

l Zero tracking: it can be reset manually or automatically, as well as dynamic zero tracking;

l Report function: built-in report statistics, reports can be generated in EXCEL format, can automatically generate a variety of real-time data reports, external USB interface, can be inserted into a U disk to export data in real time, and grasp the production status at any time; provide factory

Parameter setting recovery function, and can store a variety of formulas, it is convenient to change product specifications;

l Interface function: standard interface is reserved, data is easy to manage, and it can communicate with PC and other smart devices;

l Self-learning: There is no need to set parameters after creating new product formula information. The self-learning function is used to automatically set the appropriate parameters of the equipment, and store them for easy recall when switching products next time. (The parameter storage entry is 2000, which can be increased).

l Operation mode: three operation modes

a. Dynamic mode: normal pipeline mode;

b. Static mode: After the material enters the weighing platform, the weighing platform s running and is weighed to improve the accuracy, which is suitable for products with less than 20 passes per minute;

c. Energy-saving mode: (optional) On the basis of mode a and b, the energy-saving mode can be turned on. Set the shutdown time when no material passes through. When the equipment is idling for this time, it will automatically stop, and it will automatically start when there are materials passing through.

l Fault self-detection: It can be self-detected: whether the motor, inverter, AD, sensor and photoelectricity are normal and the cause of the fault, as well as the guide detection of the cylinder, solid state relay, and solenoid valve. It is convenient for non-professionals to check and maintain.

l Peripheral equipment communication: standard RS-485 and RS-232 dual communication port output.

a. The RS-485 interface is MODBUS, RTU standard protocol, but the write address (57600bps, 8, N, 1, slave number 3) can be modified by itself and cannot be modified.

b. (Optional) The RS-232 interface is a custom protocol, and you can set the content of the command to send by yourself. (57600bps, 8, N, 1) can be modified.

l External communication equipment such as printers or inkjet printers can also be connected with front and rear packaging machines and production equipment to feedback weighing results so that formula parameters can be automatically modified.

l Chinese input method

a. The recipe name can be input in Chinese, which makes it more intuitive to find and switch recipes.

b. With the RS-232 communication port, it can send Chinese characters of Unicode strings to peripheral devices. (Suitable for external printers or marking machines that need to print Chinese characters).

Technical Data Sheet

|

model |

LCW2512 |

|

power supply |

AC220V±10% 50HZ (60HZ) |

|

rated power |

0.1KW |

|

Single weighing range |

≤200g |

|

Weighing accuracy range |

±0.1g~±0.3g |

|

Minimum scale |

0.01g |

|

transfer speed |

20~60m/min |

|

top speed |

180 pcs/min |

|

Weighing material size |

≤100mm(L)*100mm(W) |

|

Weighing table conveyor belt size |

250mm(L)*120mm(W) |

|

Product Size |

900mm(L)*500mm(W)*1250mm(H) |

|

Removal method |

Blow/Pusher |

|

Control System |

High-speed A/D sampling controller |

|

Preset product number |

2000 |

|

Operation direction |

Facing the machine, left in and right out |

|

External air source |

0.6-1Mpa |

|

Air pressure interface |

Φ8mm |

|

working environment |

Temperature: 0℃~40℃, Humidity: 30%~95% |

|

Body material |

SUS304 stainless steel |

Main configuration table

|

brand |

name |

Specifications/Models |

(Single machine) quantity |

|

Willen |

touch screen |

TK6071IQ 7 inch |

1 |

|

Toledo |

sensor |

Toledo 10KG |

1 |

|

Omron |

switching power supply |

S8JC-C100 24C |

1 |

|

Somo |

master switch |

SLD2(3LD2-32A) |

1 |

|

Siemens |

Inverter |

V20 inverter single-phase 220V 0.12KW |

1 |

|

Seiko |

motor |

Three-phase 220V 25W |

3 |

Related products

More>>-

Factors influencing the detection effect of metal detector

Impact of product composition: metal detector mainly detects metal according to the conductivity of the article. Therefo...

Related News

More>>- Sensitivity setting and precautio... 2022-08-16

- Introduction and parameters of me... 2022-08-16

- Precautions for use of needle det... 2022-08-14

- Daily maintenance of metal detectors 2022-08-10

- Metal detector menu key function ... 2022-08-09

- Metal detector installation preca... 2022-08-08

- Overview of Muying LMD Metal Dete... 2022-08-07

- What are the characteristics of m... 2021-10-19